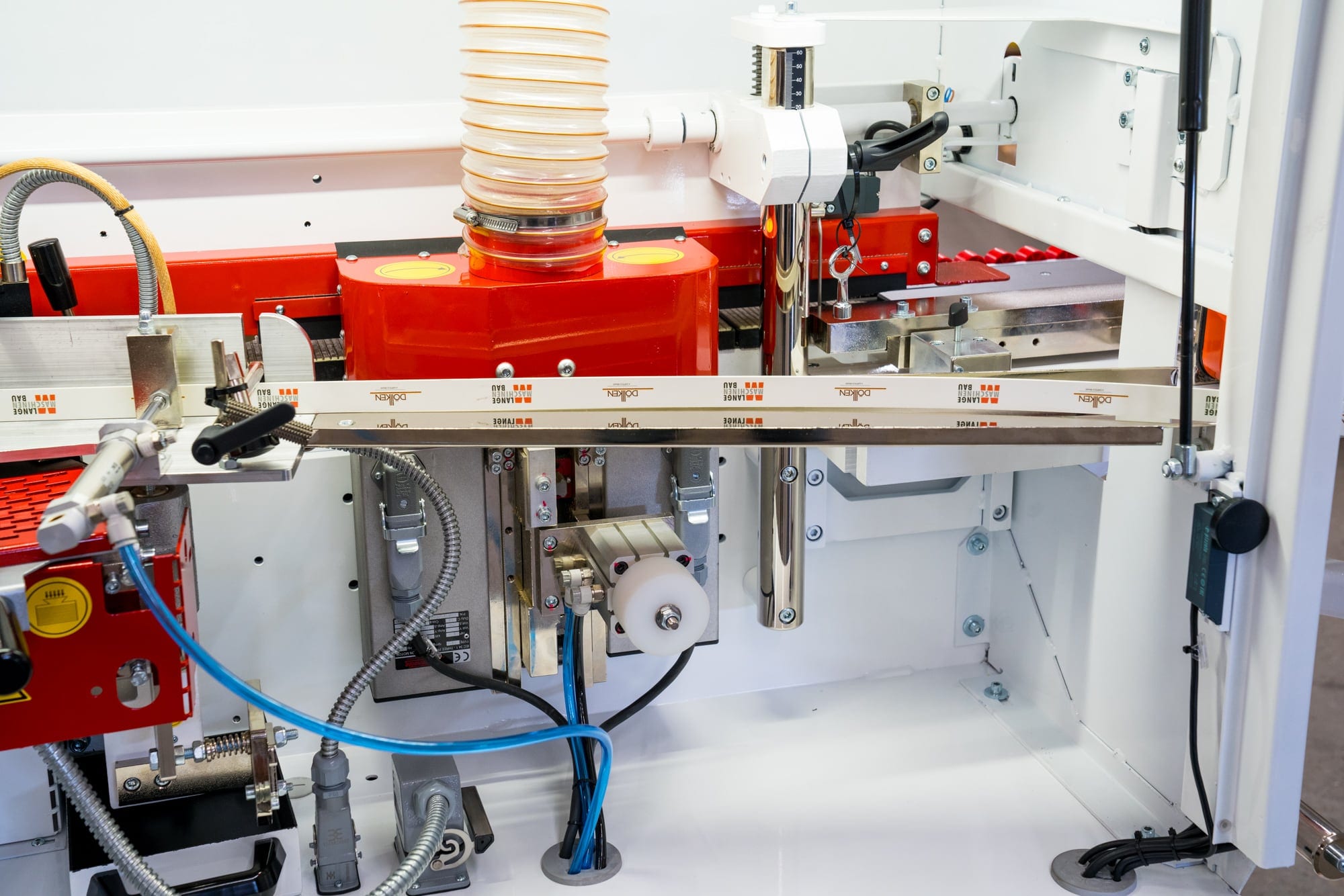

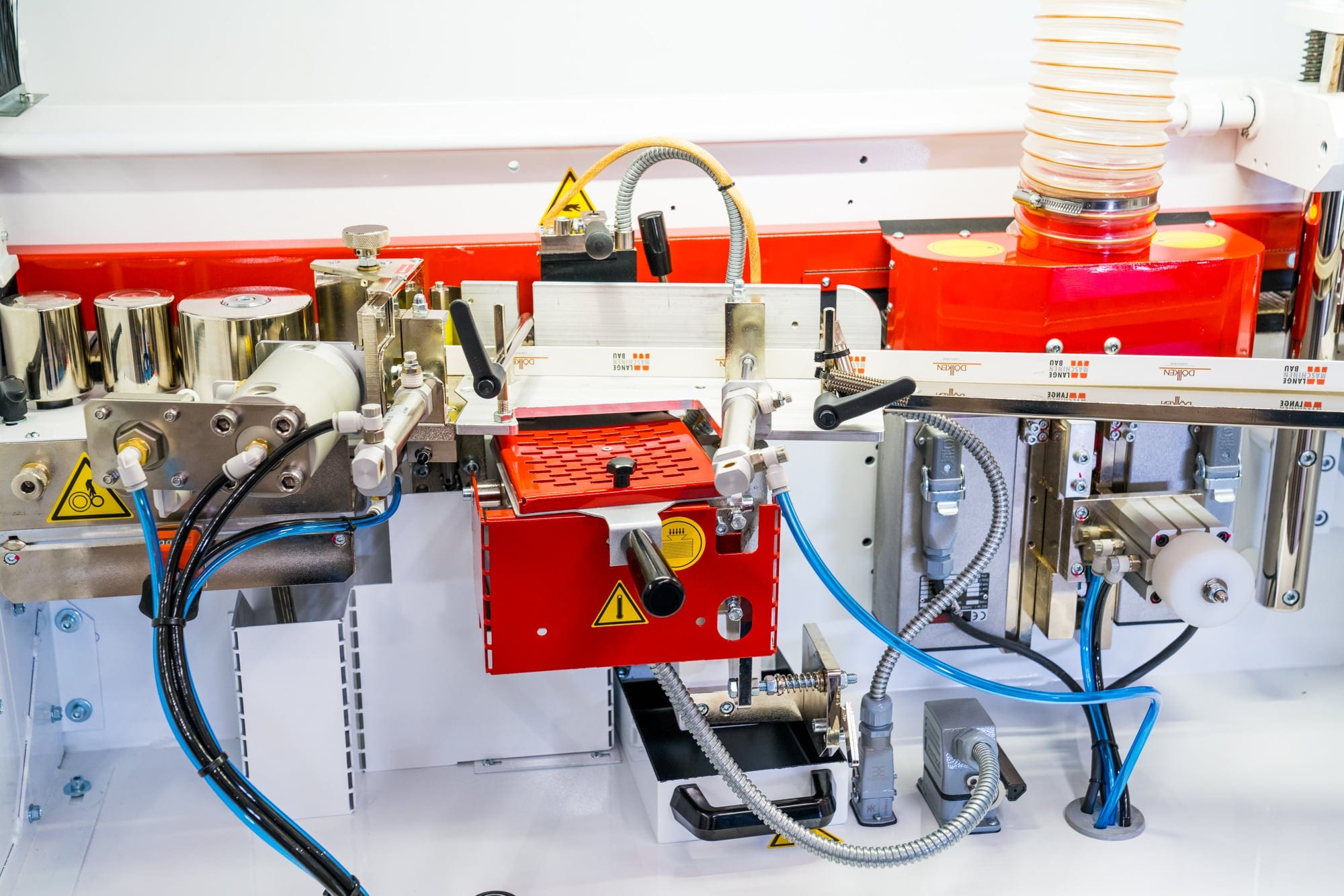

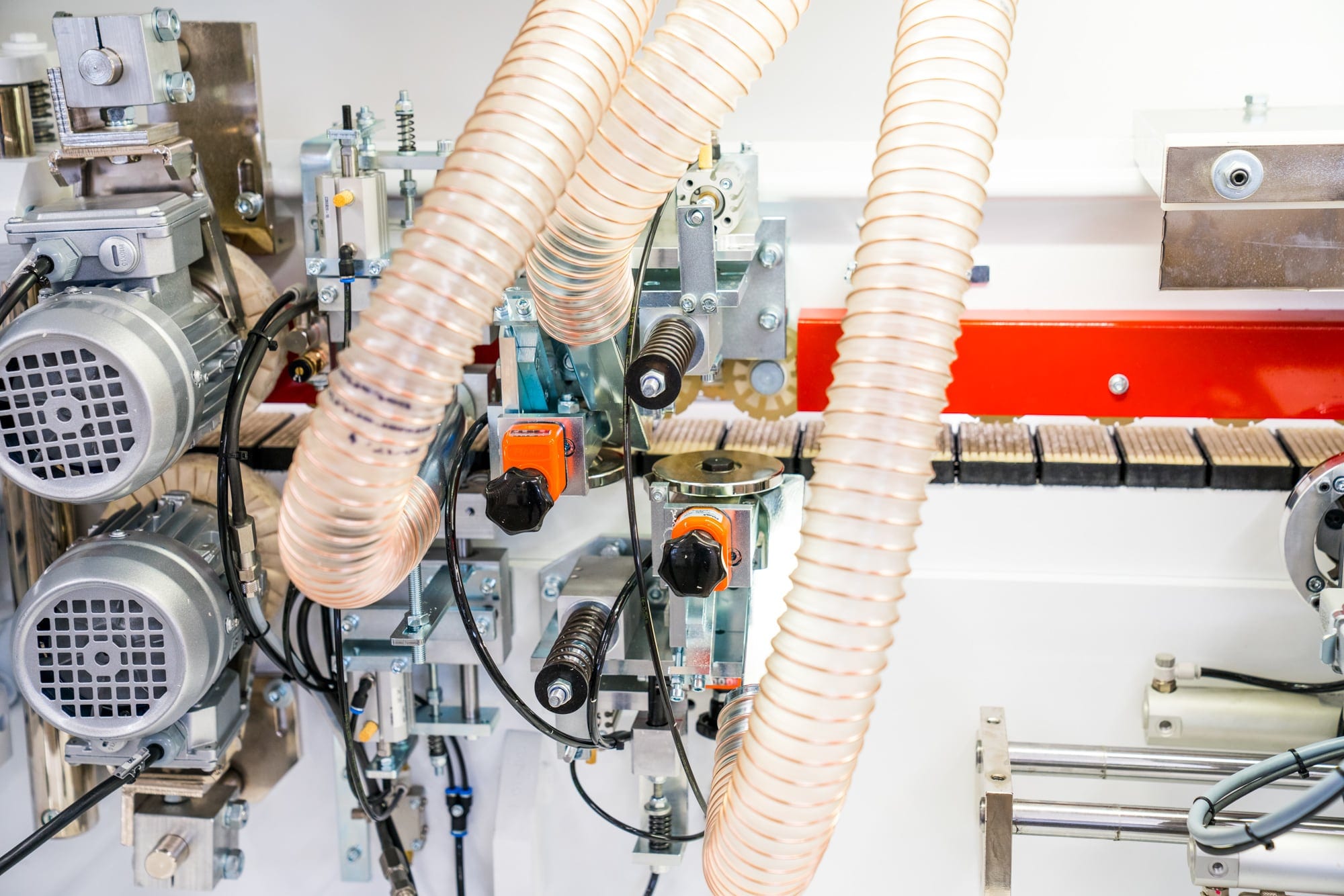

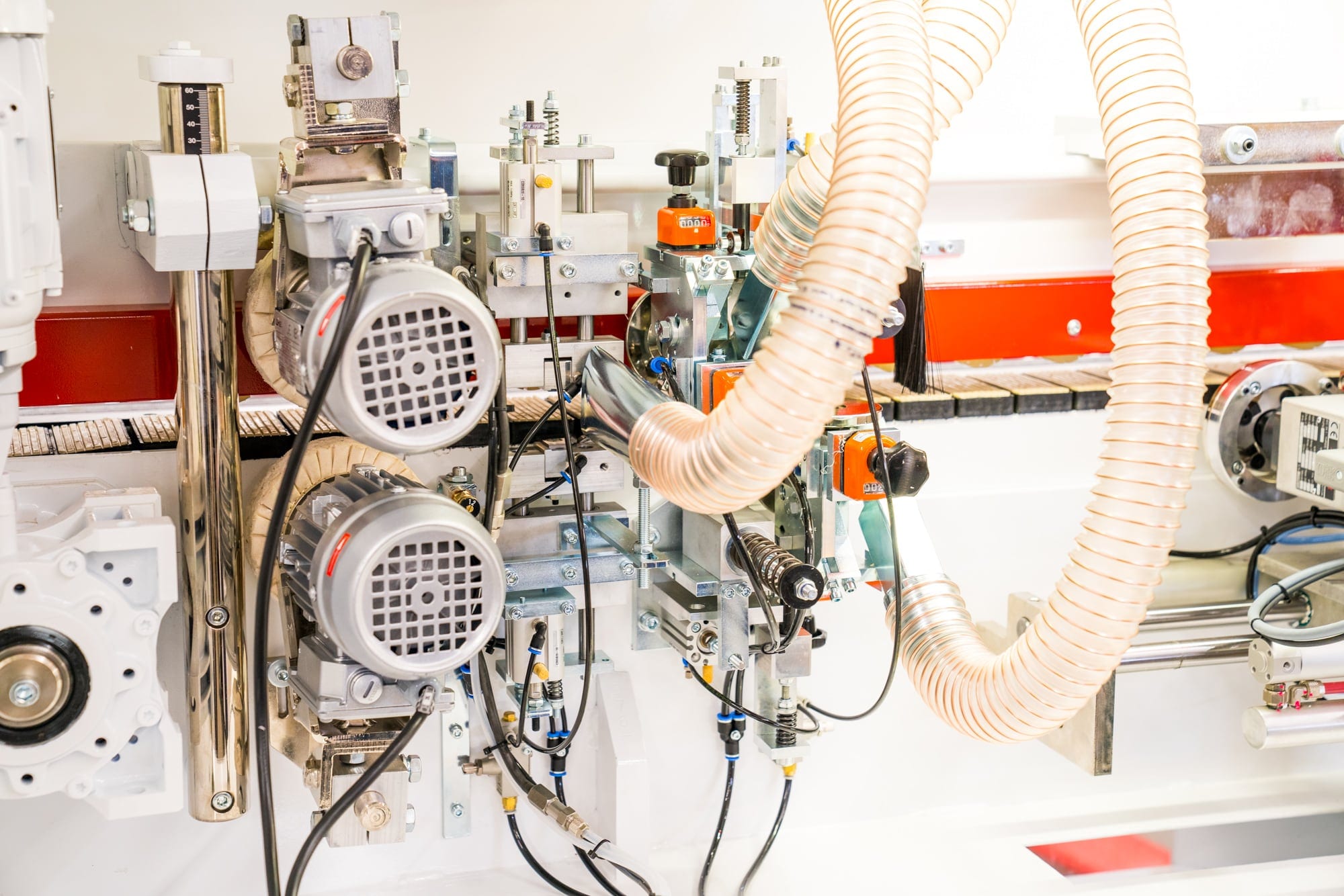

Edge Banding Machine B80KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-motor with milling head to perform the front and rear trim cut cycles, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 2.0mm (3mm Optional) and of 8 – 50mm work piece thickness.

Edge Banding Machine B85K

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0mm and of 8 – 50mm work piece thickness. Speed: 7,0 m/min. • 2 spaces for finishing units • 5,6“ Colour Touch screen

Edge Banding Machine B85KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0mm and of 8 – 50mm work piece thickness.Speed: 7,0 m/min. • 2 spaces for finishing units • Rotatable 7,0“ Colour Touch screen

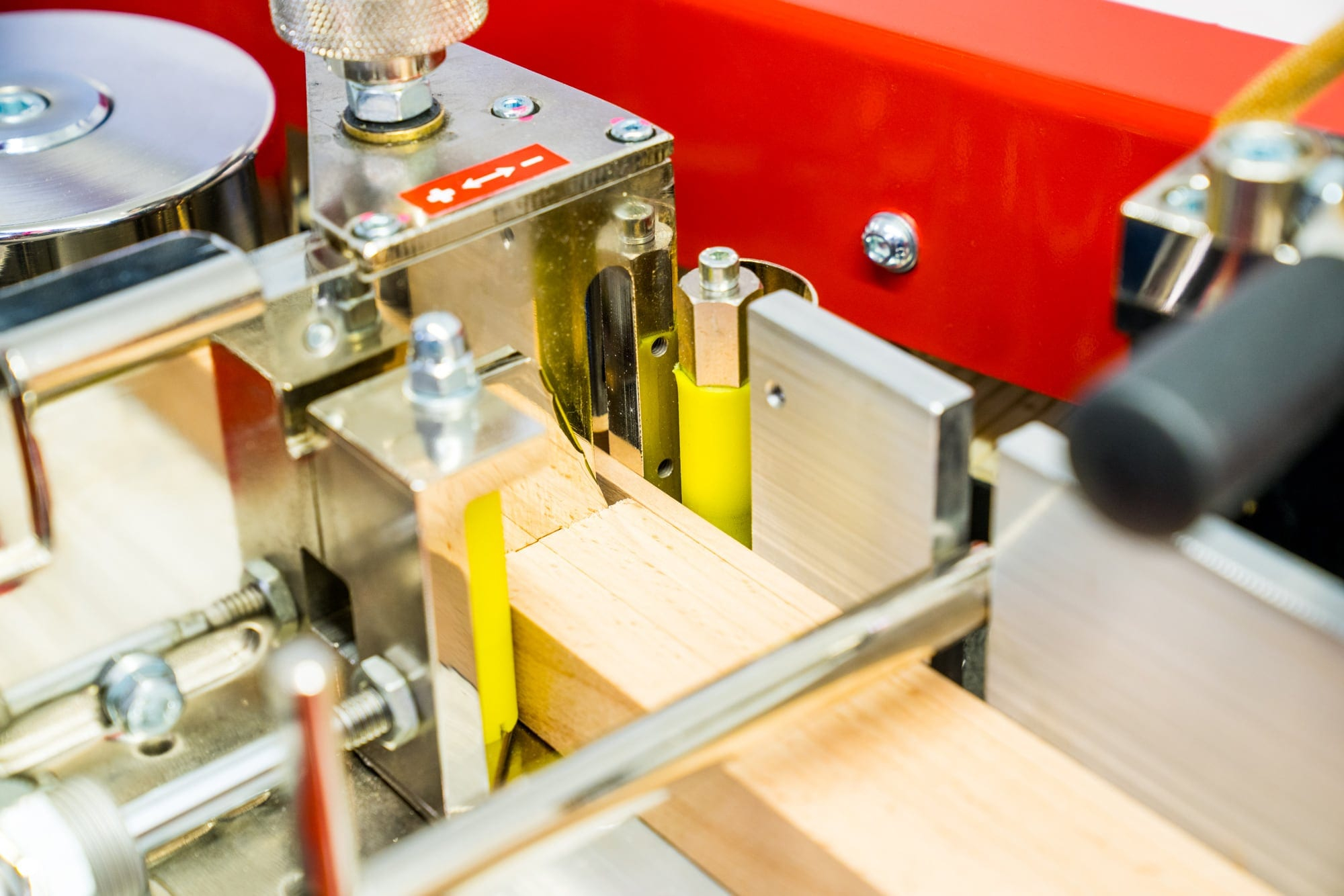

Edge Banding Machine B85KFE

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixedlengths from 0.4 – 3.0 mm and of 8 – 50 mm work piece thickness. Speed: 7,0 m/min. • 2 spaces for finishing units • Rotatable control panel with 7,0“ Colour Touch screen

Edge Banding Machine B90K

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and extendable work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0 / 5.0 mm and of 8 – 60 mm work piece thickness.

Edge Banding Machine B90KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and extendable work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

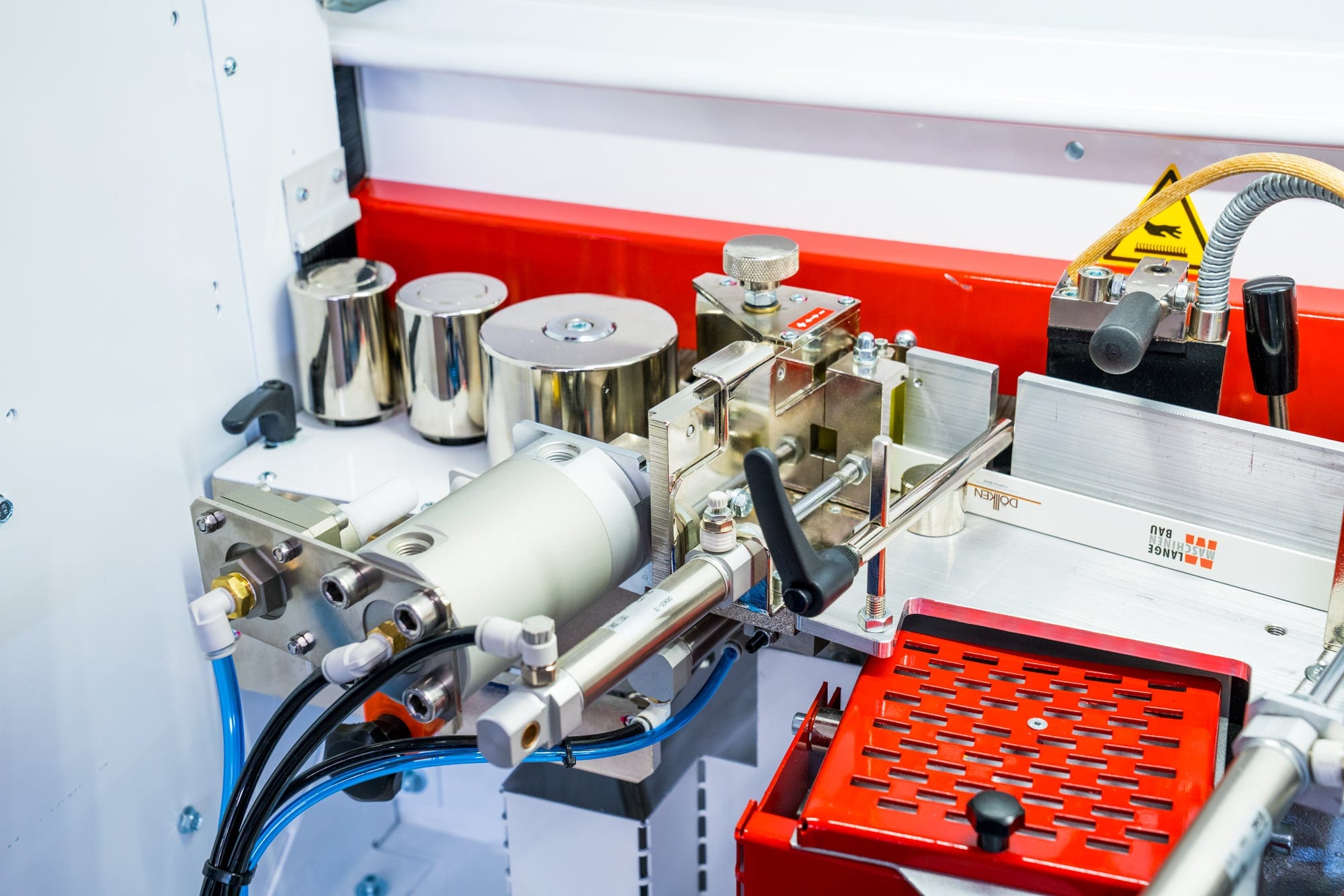

Edge Banding Machine B95KFE

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), 2-motor HF-cut-off saw station, HF-top and bottom Multiprofile milling unit, 2-motor corner rounding unit, chain feed, motorized beam pressure with encoder and ball-bearing double roller top pressure, extendable work piece support, signal lamp for work piece sequence, synchronization of working units by encoder as well as L-Motion control (18-axis). For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/5.0 mm and of 10 – 60 mm work piece thickness. Centralised dusting system for all working units.

• Speed: 10,0 m/min

• 3 spaces for finishing unitss

• 10“ Colour Touch screen

Edge Banding Machine B100K

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0 mm/8.0mm and of 8 – 60 mm work piece thickness.

Edge Banding Machine B100KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0mm / 8.0mm and of 8 – 60mm work piece thickness.

Edge Banding Machine B100KFE

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0,4 – 3,0 mm/8,0 mm and of 8 – 60 mm work piece thickness.

Kantenanleimmaschinen

Kantenanleimmaschinen