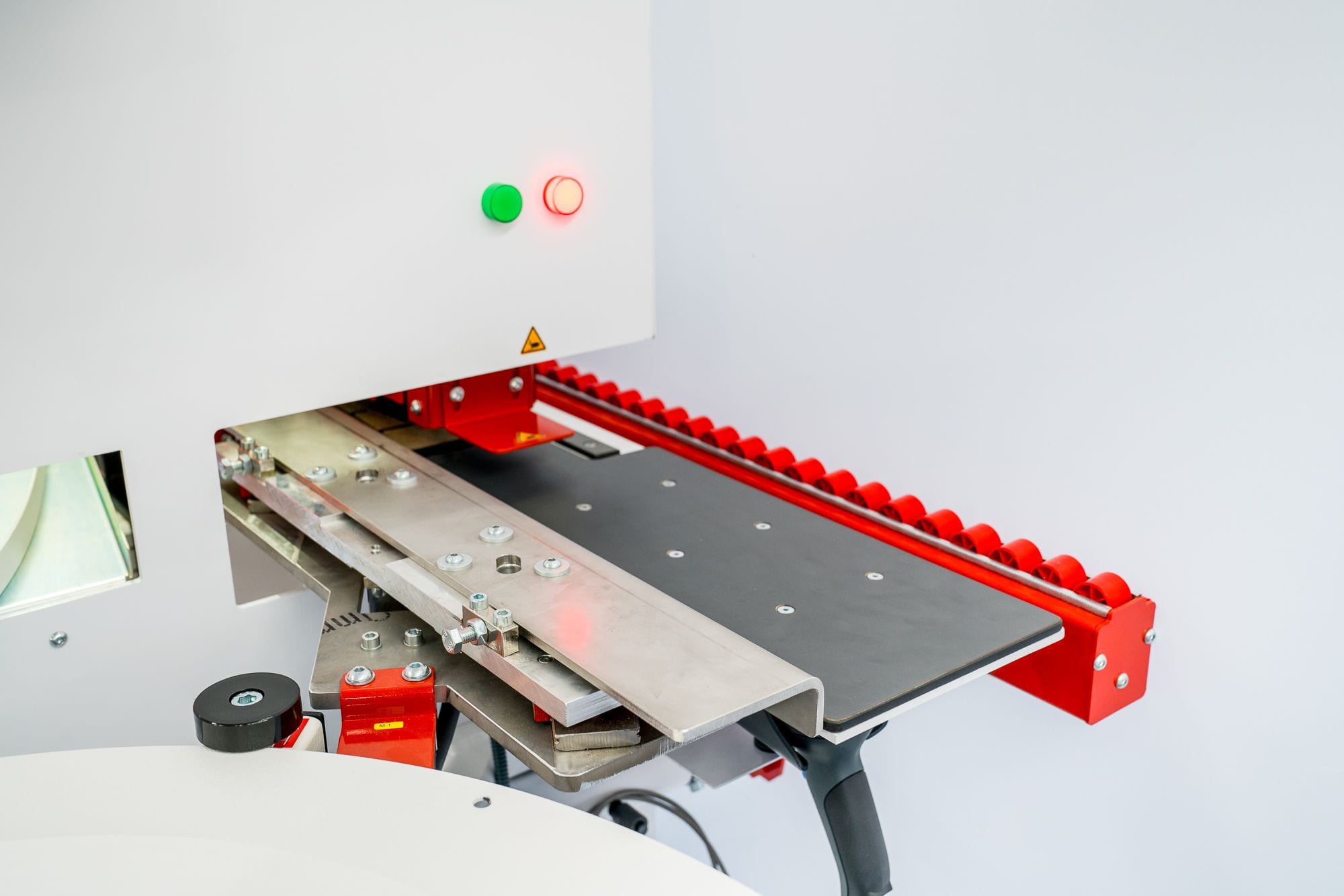

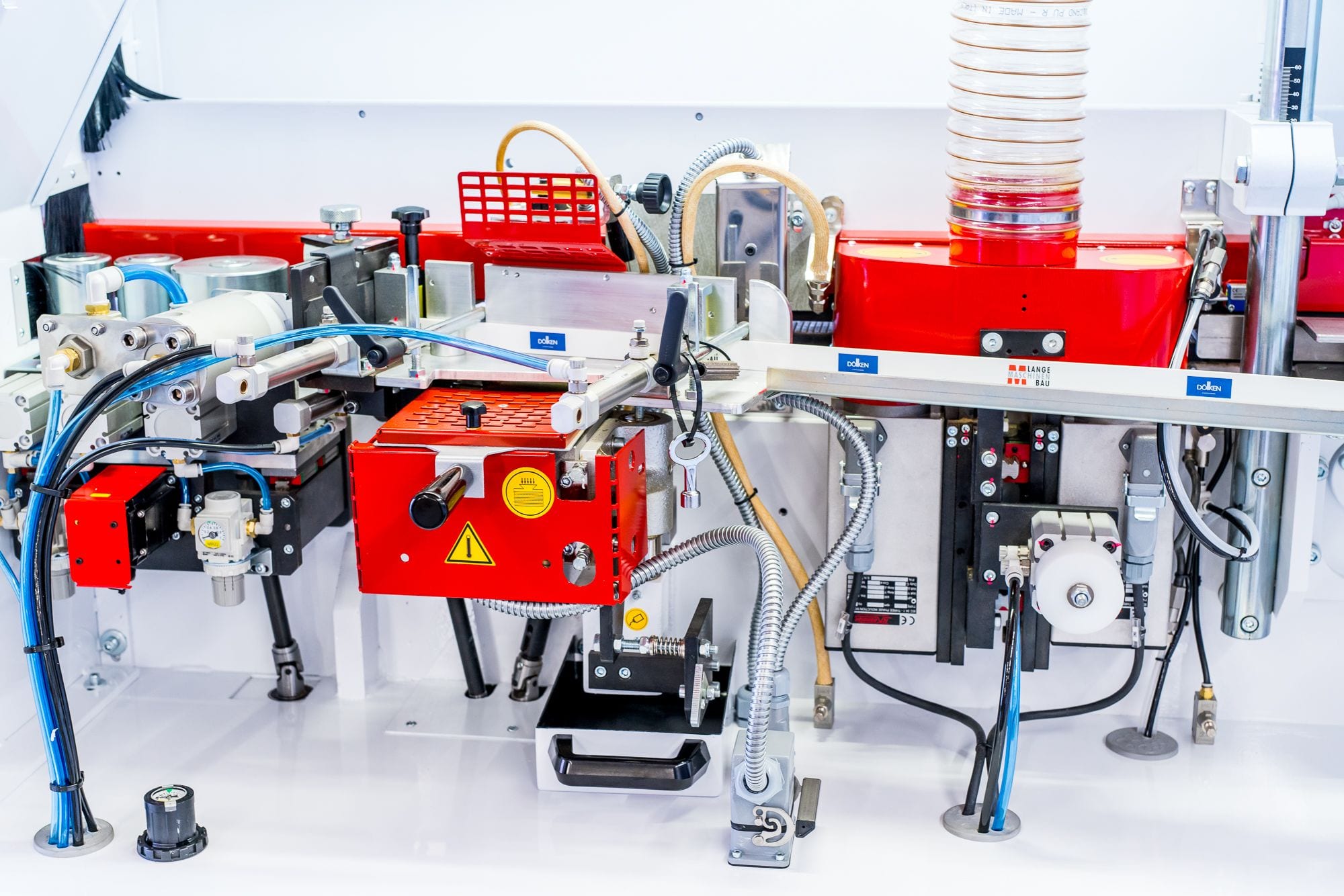

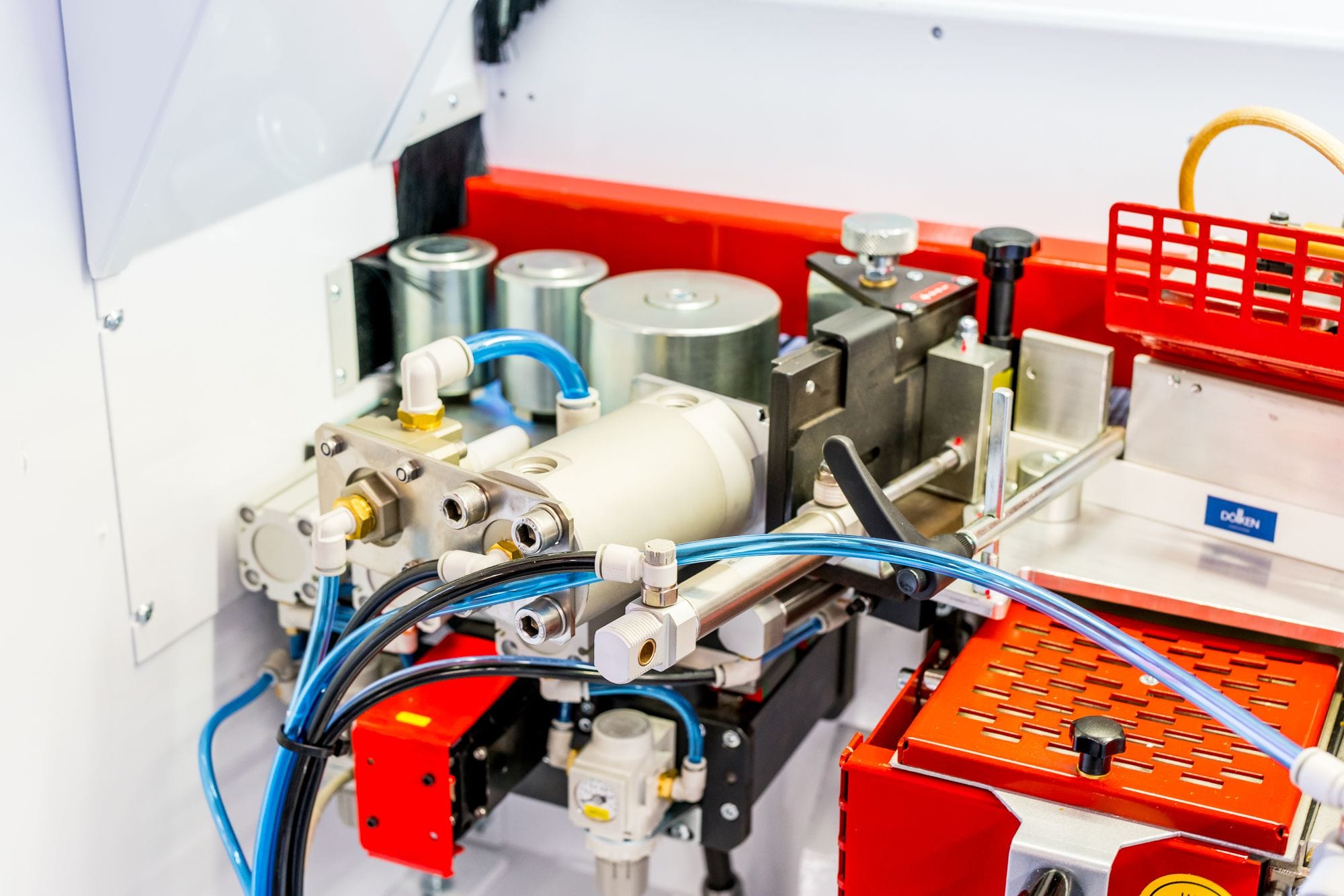

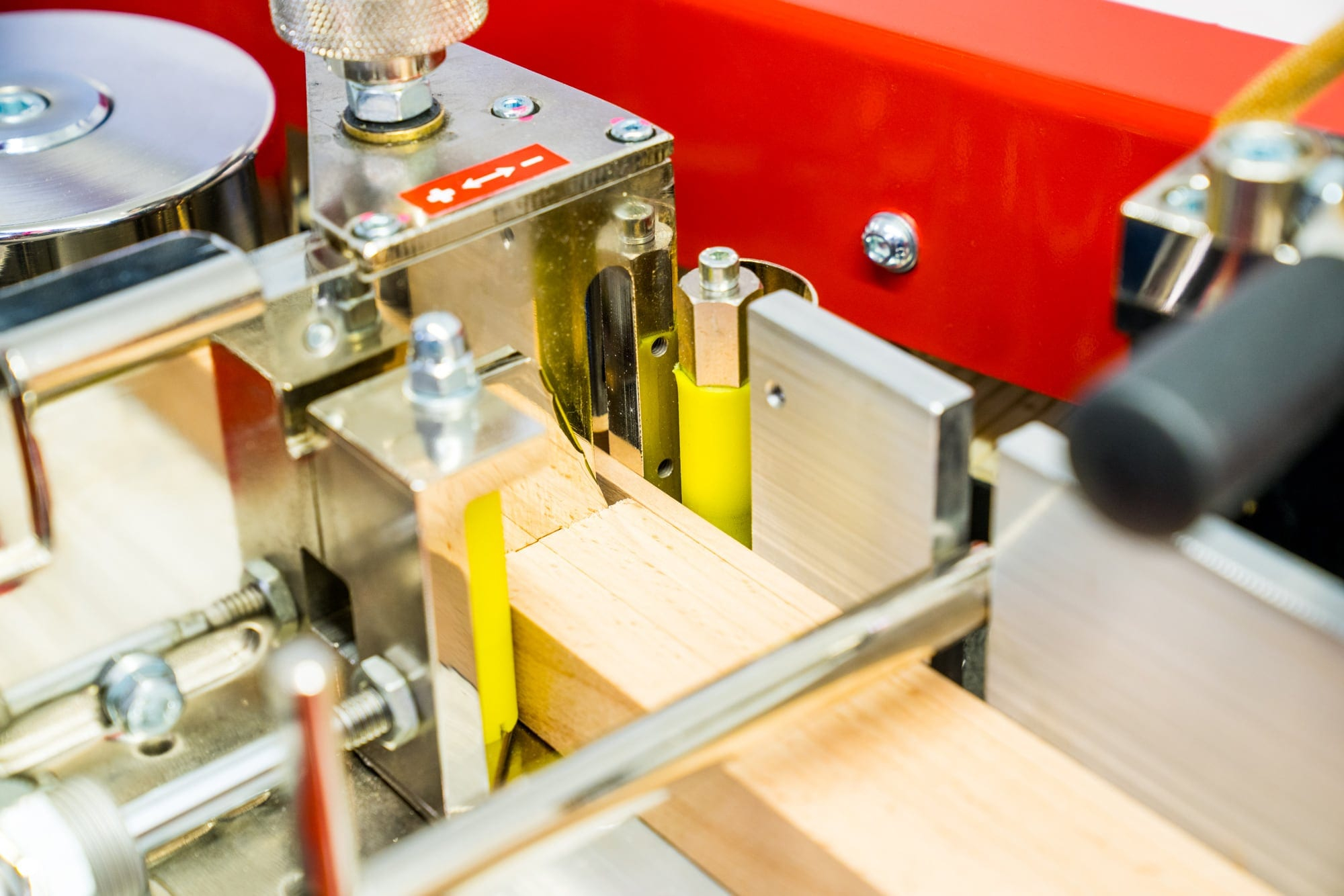

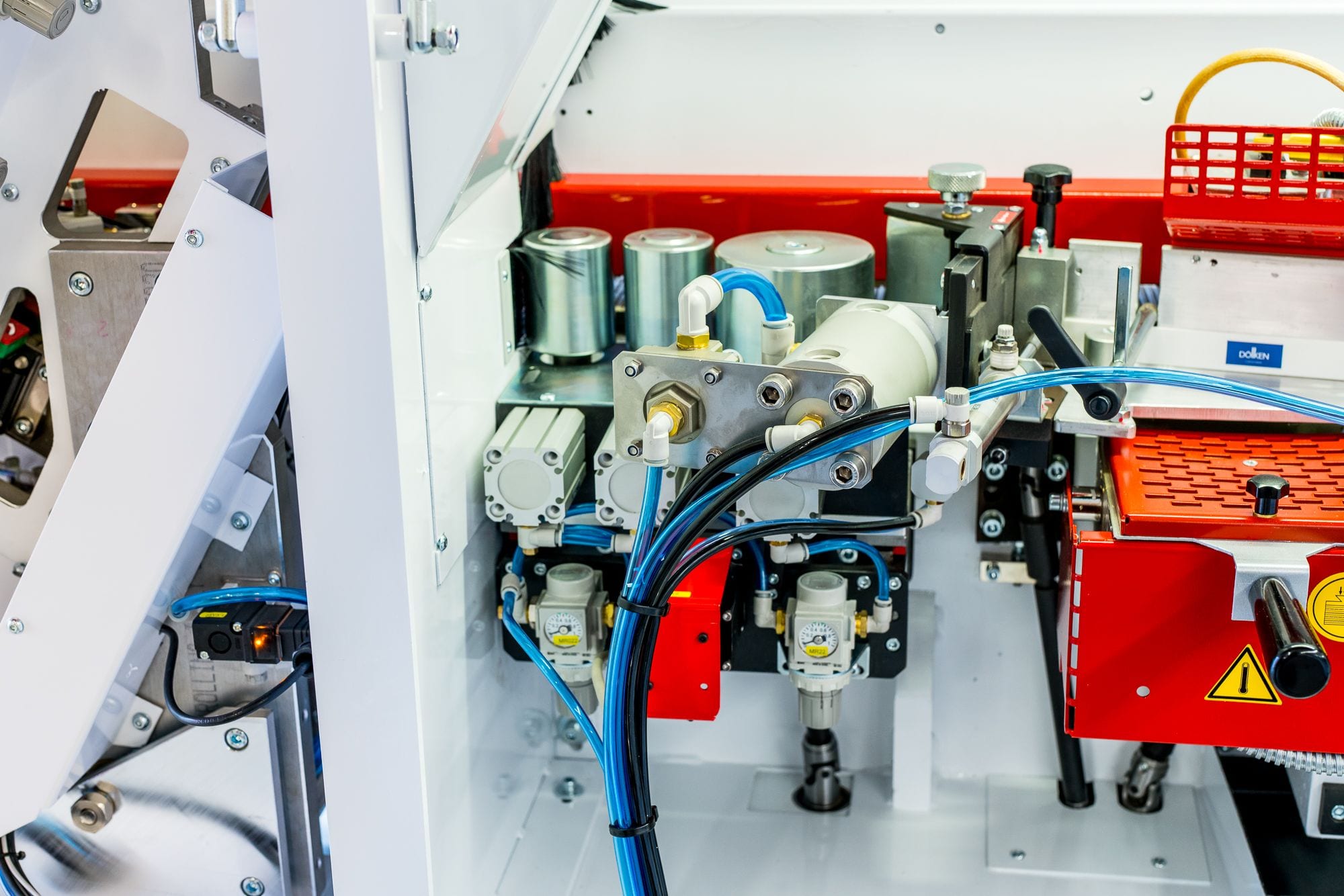

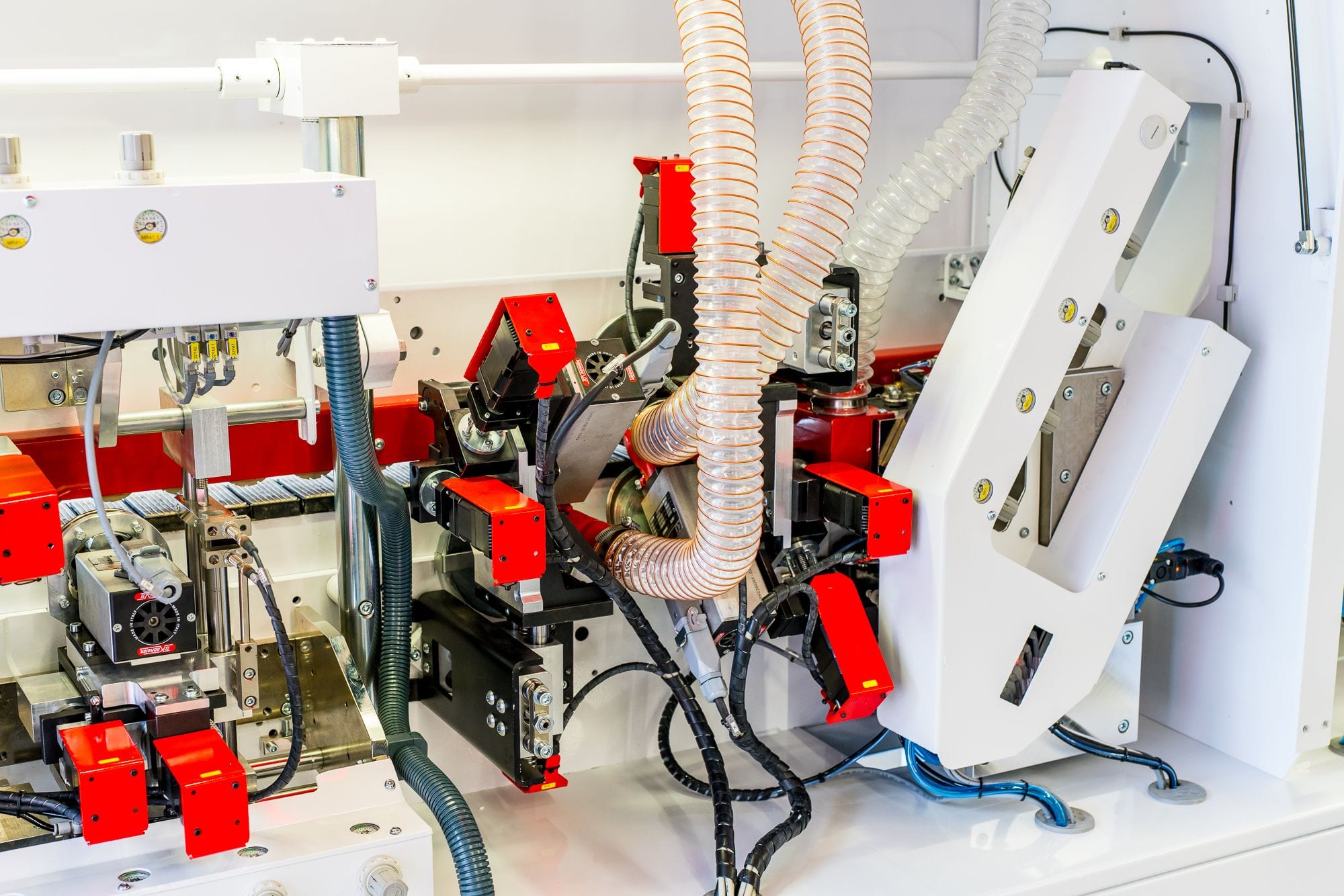

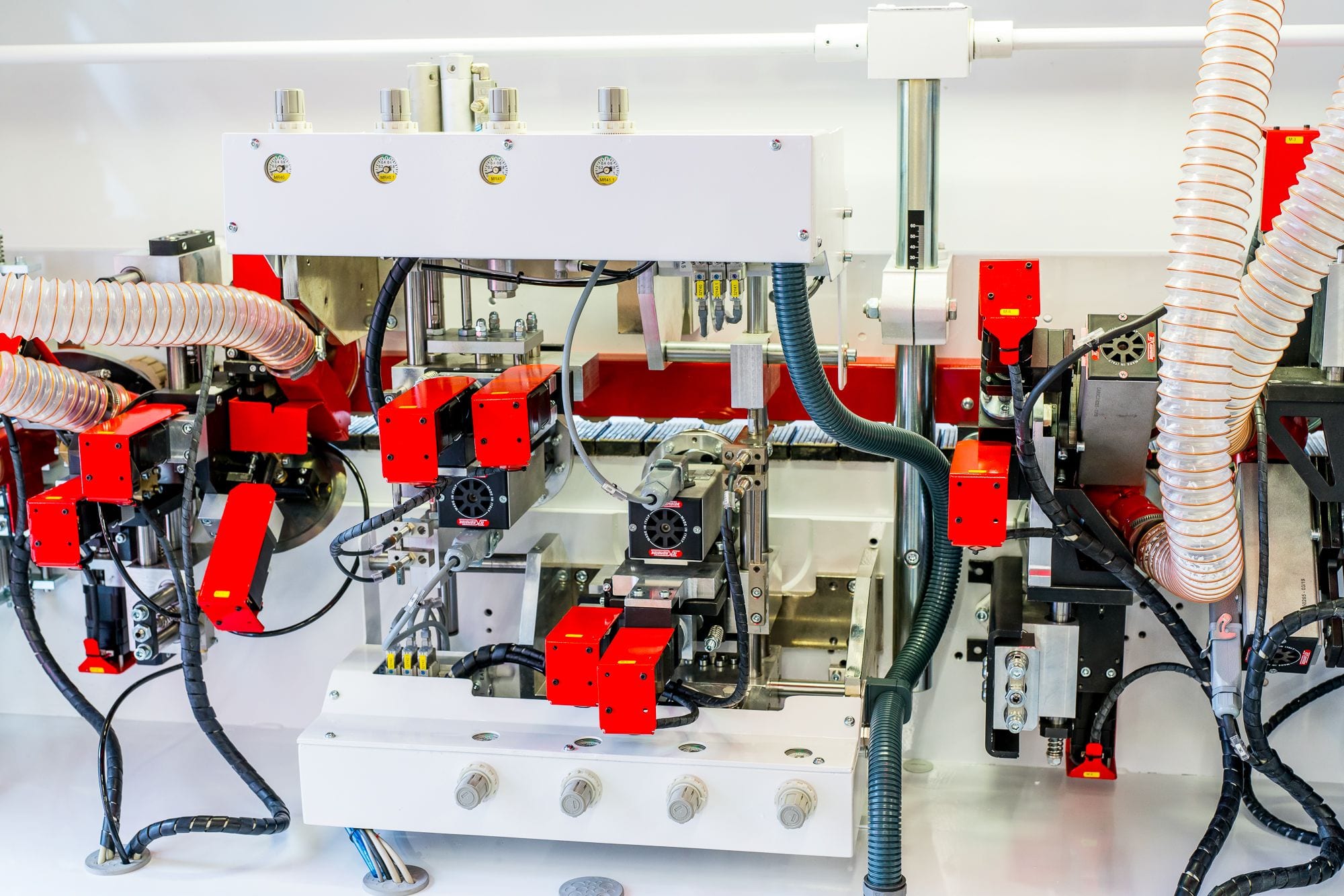

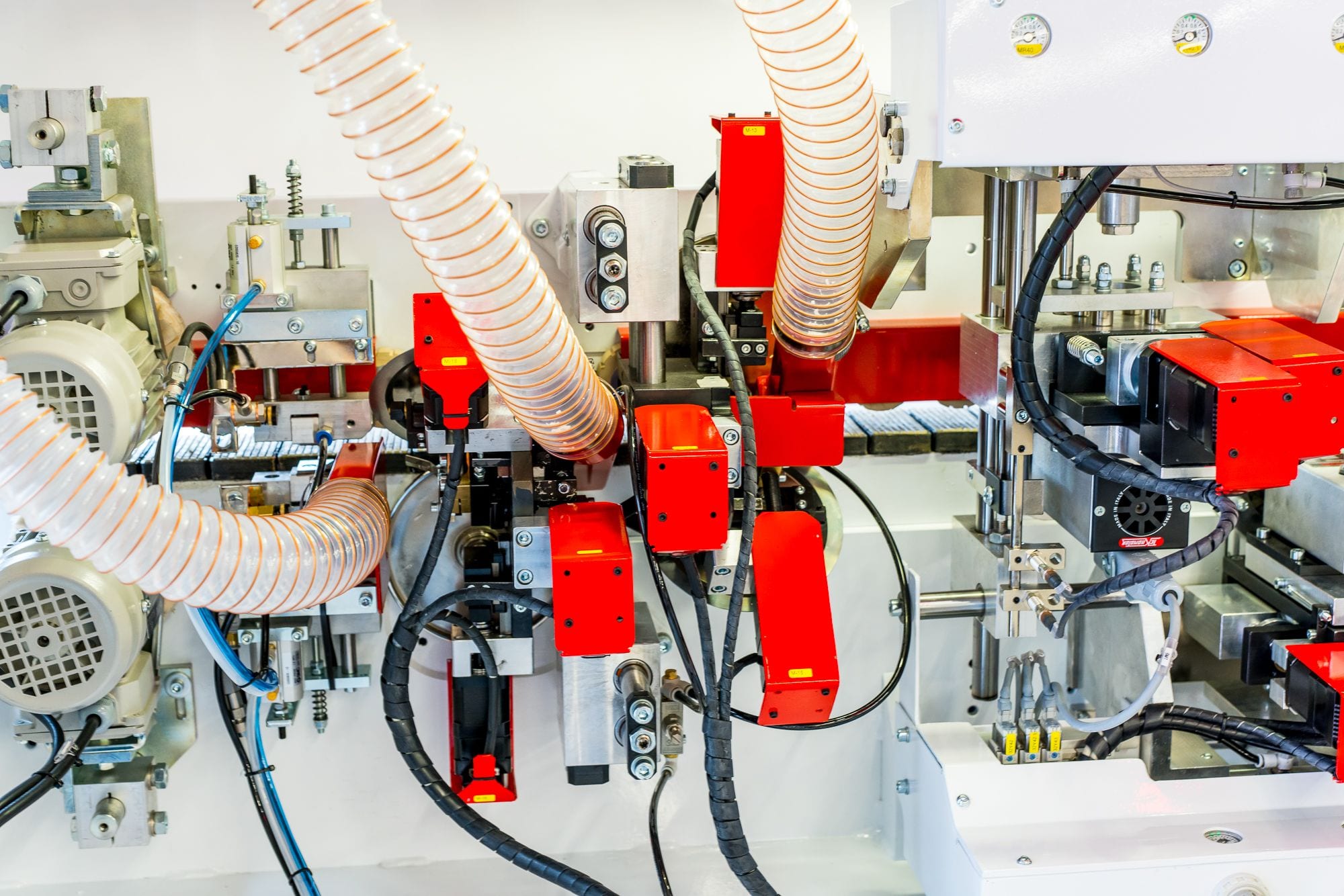

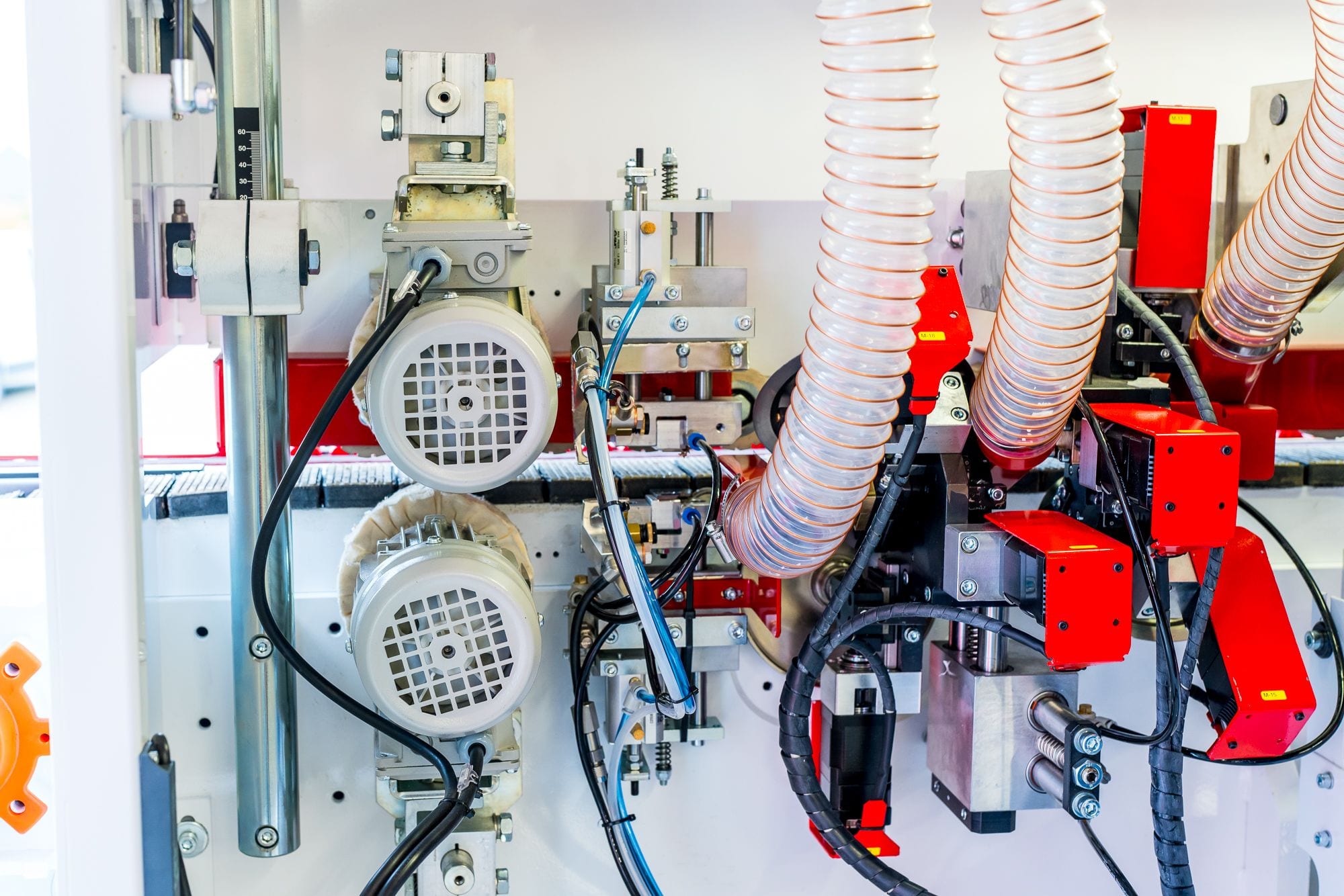

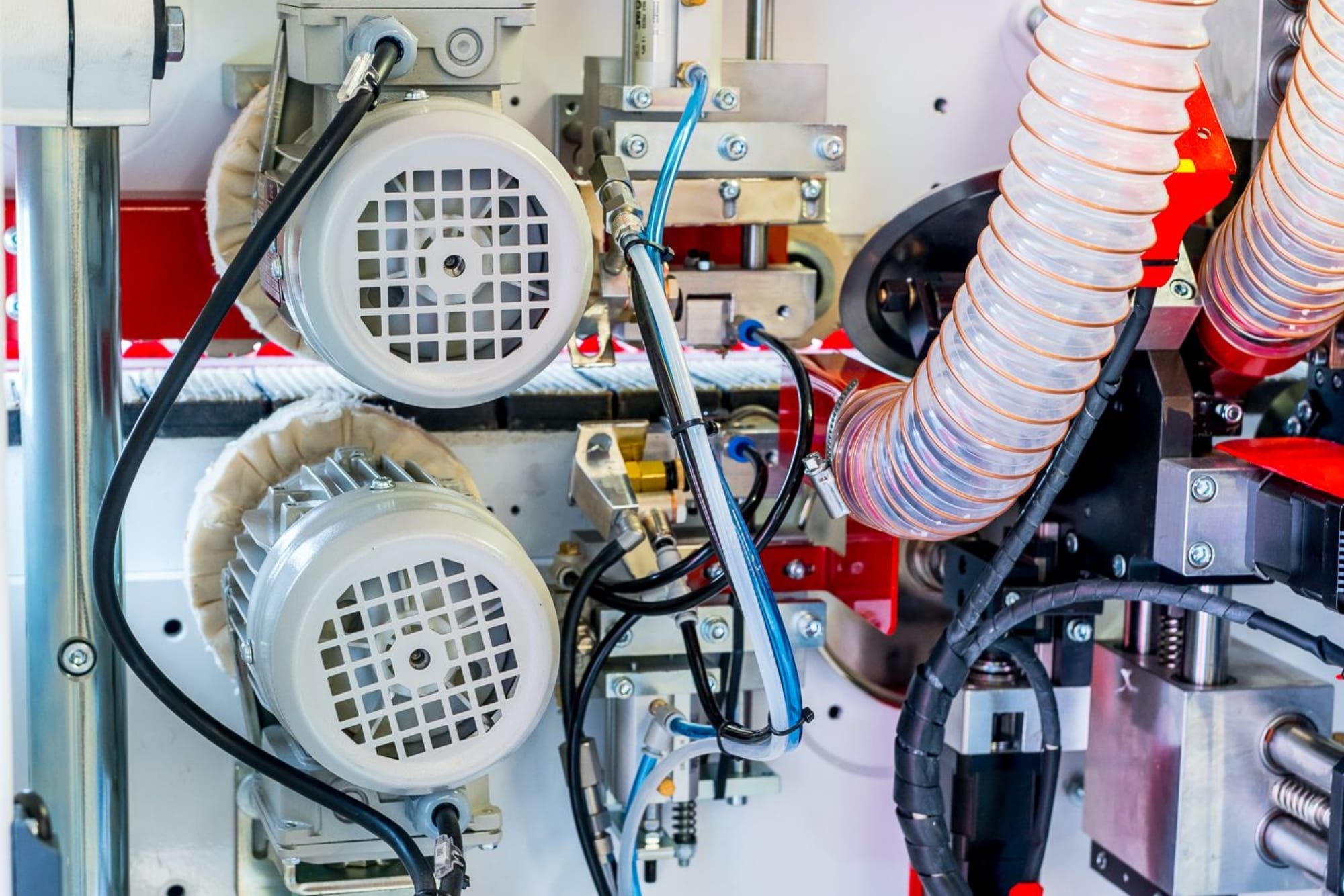

Edge Banding Machine B100KFE-N

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, grooving unit, corner rounding unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0,4 – 3,0 mm/8,0 mm and of 8 – 60 mm work piece thickness.

Edge Banding Machine B100KFE-N

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, grooving unit, corner rounding unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0,4 – 3,0 mm/8,0 mm and of 8 – 60 mm work piece thickness.

Edge Banding Machine B80KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-motor with milling head to perform the front and rear trim cut cycles, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 2.0mm (3mm Optional) and of 8 – 50mm work piece thickness.

Edge Banding Machine B72K

Compact and flexible in the smallest of spaces.

In just 1.60 m of length, workpieces receive their finishing touches.

Equipped with a Teflon-coated glue pot, a pre-cutting unit, and a HF multifunctional milling unit. Two free spaces for finishing units, such as a glue scraper and polishing unit, are provided. Easy operation via a 3.5" color touchscreen.

Edge Banding Machine B72KF

Compact and flexible in the smallest of spaces.

In just 2.13 m of length, workpieces receive their finishing touches.

Equipped with a 1.1 kW high-frequency motor, a pre-milling unit with a diamond-tipped spiral jointing cutter, a Teflon-coated gluing unit, a pre-trimming unit, and a HF multifunctional milling unit. Two free spaces for finishing units, such as a glue scraper and polishing unit, are provided. Easy operation via a 3.5" color touchscreen.

Edge Banding Machine B85K

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0mm and of 8 – 50mm work piece thickness. Speed: 7,0 m/min. • 2 spaces for finishing units • 5,6“ Colour Touch screen

Edge Banding Machine B85KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0mm and of 8 – 50mm work piece thickness.Speed: 7,0 m/min. • 2 spaces for finishing units • Rotatable 7,0“ Colour Touch screen

Edge Banding Machine B85KFE

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixedlengths from 0.4 – 3.0 mm and of 8 – 50 mm work piece thickness. Speed: 7,0 m/min. • 2 spaces for finishing units • Rotatable control panel with 7,0“ Colour Touch screen

Edge Banding Machine B90K

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and extendable work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0 / 5.0 mm and of 8 – 60 mm work piece thickness.

Edge Banding Machine B90KF

One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and extendable work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

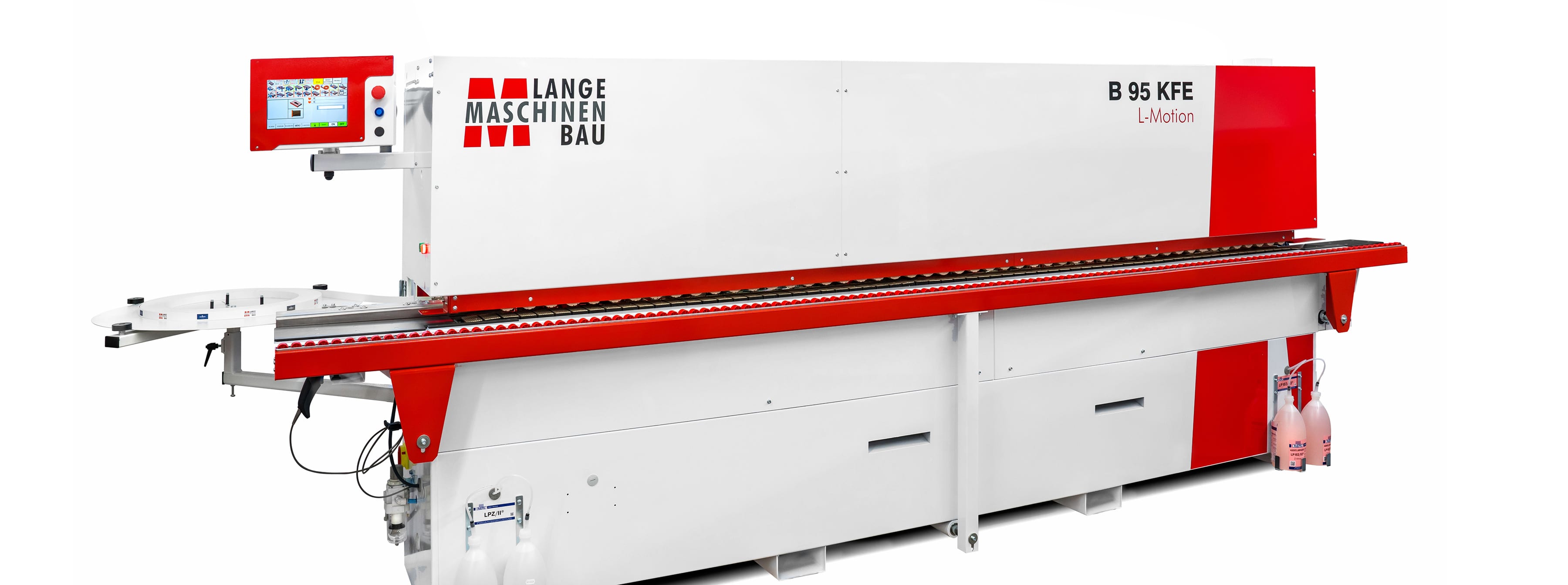

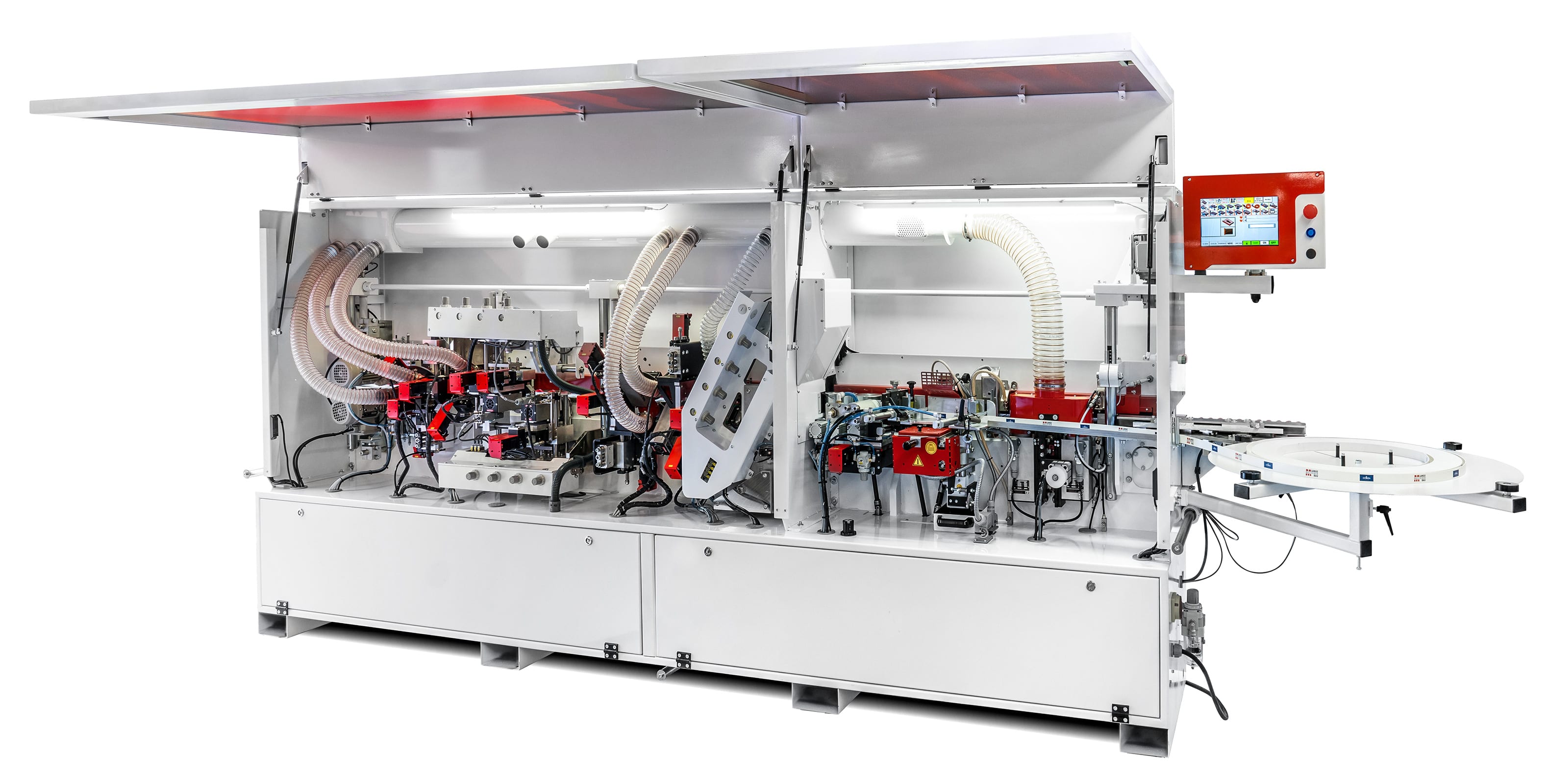

Kantenanleimmaschinen

Kantenanleimmaschinen